Small Cell Test, Reference Solution

Brochures

Small Cell Test, Reference Solution

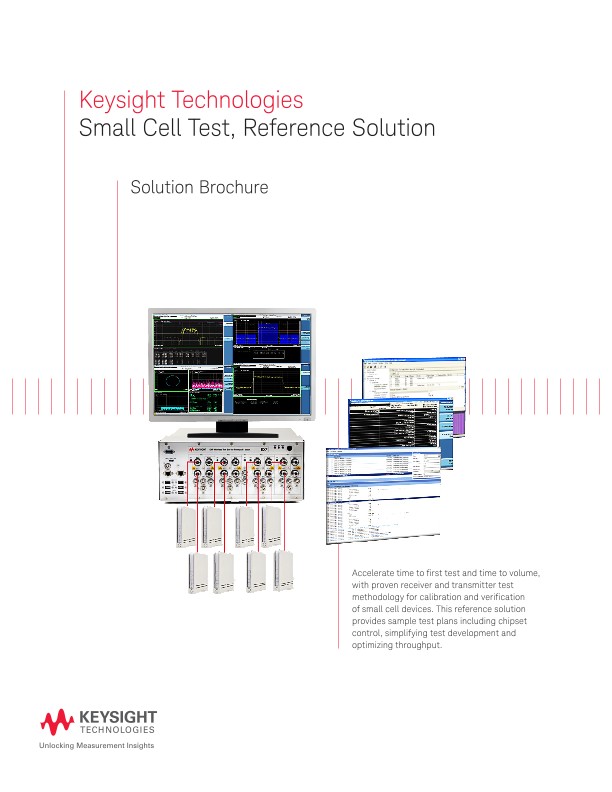

Accelerate time to first test and time to volume, with proven receiver and transmitter test methodology for calibration and verification of small cell devices. This reference solution provides sample test plans including chipset control, simplifying test development and optimizing throughput.

Small Cell Test Challenges

The small cell market is characterized by evolving standards, interworking radio access technologies and increasing production volumes.

Time-to-market can make the difference between the success and failure of a commercial project. Test development can consume valuable resources and extend project timelines. The increasing complexity of evolving standards means that test developers are never standing still, needing to adapt to the latest requirements.

Demand for small cells is increasing, volumes are expanding and devices require more intensive test: multiple radio-access-technologies, multiple carriers more RF ports to support MIMO. This drives the need for more testing per device.

Cost of test is under increasing pressure, driving the need for reduced test times and more test capacity packed into a given space or footprint.

The ability to make consistent measurements in different environments is essential to an efficient production machine. Failures on the production line need to be replicated, verified and resolved quickly, often across geographies and time zones.

Small cell Reference Solution

The Keysight small cell test, reference solution is designed around typical test plans, including calibration steps and performance test. Comprehensive test automation examples control both the DUT and the measurement hardware, which means you can easily run calibration and verification sequences from start to finish with simple pass/fail outcomes.

Keysight is collaborating with leading chipset vendors to implement their current measurement plans and aligning on a roadmap to next generation designs. The Keysight reference solution includes test automation with example test steps that can be built into fully-automated test sequences. You can also call Keysight’s code from your own choice of test executive, or use the supplied examples to validate tests you have coded in your own automation environment.

Whether you are verifying a design or testing for production, additional debug capability is on hand, so you can focus in on the details. With the aid of the graphical user interface, you can easily understand how your design is performing and quickly get to the root of any problems. And if you need to reduce your test time there is a timing analyzer to help you optimize test flow.

With up to 16 RF ports in a single 19” rack instrument, the reference solution can be scaled to provide superior port density and the ability to connect multiple multi-port DUTs simultaneously. The multiple RF sources and RF analyzers can independently create or analyze a signal sequence for the DUT, further improving test efficiency and throughput.

This solution uses the same measurement software that you find in Keysight’s signal analyzers and signal generators, so you can be sure of consistency between different hardware platforms.

Drive down your cost of test:

- Save engineering time spent on test development and debug

- Improved throughput and asset utilization

- Consistent measurements from development bench to manufacturing

Accelerate time to test and time to volume

- Example automation for calibration and performance test of popular chipsets

- Highest port density within the smallest footprint

- Fast execution with powerful analysis to aid optimization

Supported technologies

- Cellular: GSM, TD-SCDMA, UMTS, LTE FDD, LTE TDD

- Wireless connectivity: WLAN

Typical calibration plan

- Downlink: Power, Frequency, IQ

- Uplink: Gain, RSSI offset

Typical verification plan

- Downlink: Power, Frequency, Error Vector Magnitute, Spectrum Emmissions Mask, Adjacent Carrier Leakage Power Ratio, Occupied Bandwidth

- Uplink: Received Signal Strength Indicator, Sensitivity

DUT utilities

- Reboot

- Command

- Query

E6650A EXF wireless test set

The EXF is a one-box tester dedicated to small-cell testing. It delivers the speed, performance and scalability you need to ramp up rapidly and lower your cost of test.

- Get up and running rapidly with cellular and WLAN chipsets

- Reduce overall test time with hardware and software elements optimized for speed

- Easily test multi-format small-cell designs that include 2G, 3G, 4G and WLAN

Software

The small-cell test, reference solution includes a test automation environment that greatly simplifies creation of a test plan and analysis of the results. With pre-defined test steps, instrument control and DUT control, you can move quickly to test results without having to spend time coding. The reference solution also includes measurement applications that can be used with the EXF as well as more traditional benchtop instruments like the MXG and MXA. For signal creation, the solution uses Signal Studio and X-Series measurement applications for signal analysis.

Test automation with example calibration and verification steps:

Move quickly to measurement with proven test methodology and optimization for popular small-cell chipsets.

Simple execution, result reporting and flow analysis:

Run test plans, analyze results against pass-fail limits and export in multiple formats. Timing analyzer provides visualization to help optimize test efficiency.

Graphical user interface and command-line interface:

Non-programmers can construct and configure calibration and test plans with simple flow control (including conditional loops).

Modular architecture:

Plug-in components provide instrument drivers, DUT drivers, calibration steps, test steps. Fast and simple to implement new test steps and custom code.