Können wir Ihnen behilflich sein?

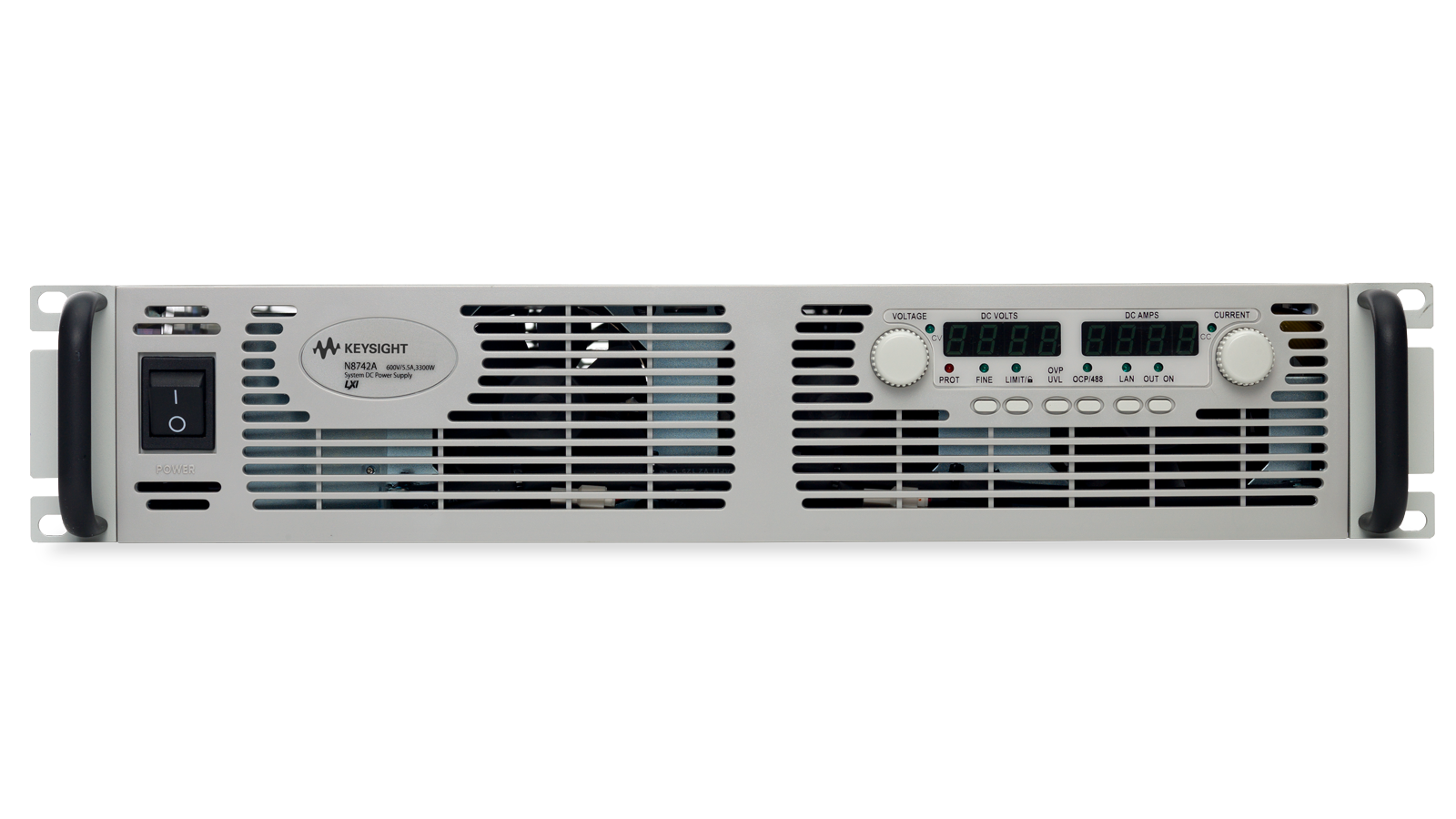

DC Power Supply

Power your next insight with precision

Save Now on Modular Power Supplies

Save 15% on eligible ATE system power supplies and modules for a limited time.

Claim Reward When You Purchase a Power Product

Choose an exclusive free gift to complement your purchase of a power product for a limited time.

What ATE or Bench DC Power Supply is correct for you?

On a bench or in a system, Keysight variable DC power supplies are ready for your application, offering optimal voltage, current, capability and performance choices.

This video will help you pick the correct variable DC power supply by understanding the critical characteristics you should consider in your selection process. Key aspects of programmable DC power supplies include available power, noise requirements, programming accuracy, available software, and more.

How to Select the Correct DC Power Supply for Your Application

Choose the Variable DC Power Supply That Is Right for You

Enhance your bench with a low-noise power supply that is easily viewable from any angle

Reduce integration and test times with a compact programmable power supply

Solve your power challenges with hardware and customized software

Extend Your Capabilities With The Right Tools

Technology is constantly changing. So too are the requirements engineers face. Get more functionality out of your existing hardware today by complementing it with the right accessories to improve productivity and the right Keysight PathWave design and test automation software to accelerate your product development.

The Power Handbook

This handbook serves as a one-stop shop for information on power-related topics, incorporating information from many of Keysight’s popular application notes. You will gain insight into the fundamentals of electrical power and DC power supplies, including defining the different types of power supplies. You’ll also learn about the key characteristics of power supplies and electronic loads.

The handbook has chapters on how to test battery performance, power converters (DC-DC and AC-DC), and solar arrays. Plus, it includes a chapter on using software to control supplies, automate tests, and analyze data.

Build Your DC Power Supplies Skill Set

Today's designs place higher demands on the DC power systems you develop, which often cause design problems.

In this eBook, our experts help you better understand DC power supply issues and provide four ways to build your DC power supply skill set so you can overcome design challenges.

10 Tips to Enhance DC Power Testing and Analysis

A power supply is an integral part of any good test system. The capability to deliver clean and accurate power to your Device Under Test (DUT) removes doubts and gives you the right results every time. Our practical tips will let you get more out of your programmable power supply. Also if you ever need to get a new power supply, you can count on these tips to help you choose the right one. Remember, more power and features do not mean a better power supply. It’s about how you use your power supply.

Featured Resources

Learn more with Keysight University

Bench Power Supply Basics

- Gain an understanding of the technology behind them

- Learn best practices for using power supplies and how to get the most out of them

Power Supply and Electronic Load Basics

- Learn how power supplies and electronic loads work

- Gain insight into maximizing the effectiveness of both instruments

DC and AC Power Fundamentals

- Learn about the basics of AC and DC power

- Gain insight into power transmission and conversion

Frequently Asked Questions About DC Power Supplies

It is a power source with an output voltage that the user can vary. Keysight variable DC power supplies allow you to change the DUT's voltage and current.

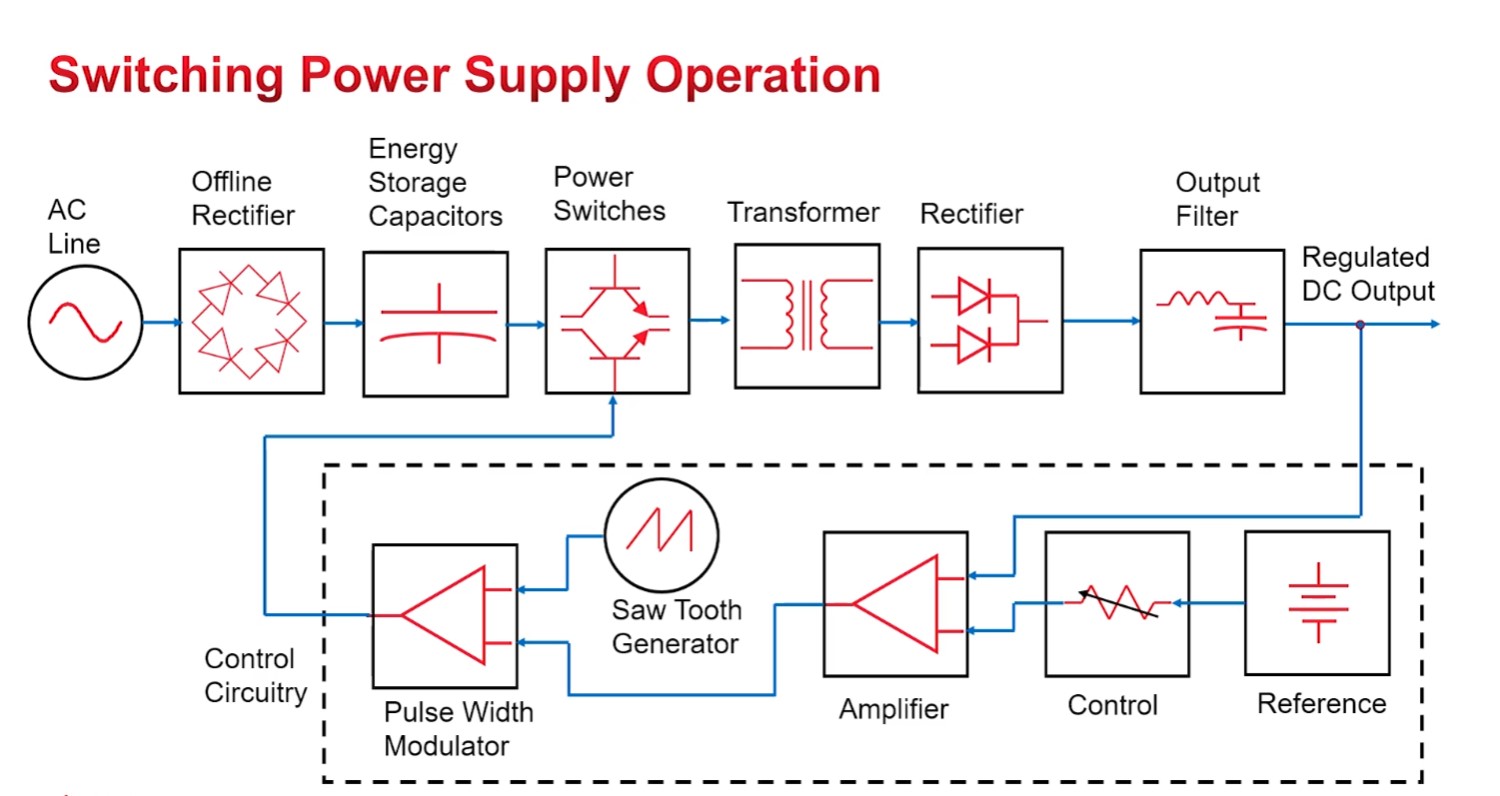

A DC power source converts alternating current (AC) power into DC power using either a linear or switching methodology. A switching power supply has higher efficiency, reduced weight, and smaller size. Linear power supplies can achieve lower noise, but modern switching supplies have minimized or eliminated this advantage.

A programmable power supply is a power source whose output voltage, output current, output power, and other electrical output characteristics can be configured or programmed at a very fine-grained level.

However, despite their sophisticated front panel controls, knobs, displays, and powerful user interface, they're not mere adjustable power supplies but far more than that. Their most unique aspect is that their power output behavior can be programmatically controlled in real-time using an external computer, as shown below.

A bench DC power supply is designed to sit on an engineer’s bench. It will typically have a large, legible display and a user interface so engineers can easily control all aspects of the power supply from the front panel. Users can also control modern bench power supplies via software. In addition, the output terminals are easily accessible from the front. Variable bench power supplies are handy tools for testing circuits, as they allow you to adjust the voltage on the fly.

Automated test equipment (ATE) system power supplies are programmable power supplies designed for ATE systems. Size is crucial; ATE power supplies with greater power density take up less rack space and reduce the factory floor space required for test equipment.

You can combine power supplies in series to increase the total power (voltage) they can deliver. The diagram below illustrates the correct connections to achieve this.

Of course, you must set each power supply output independently so that the voltages sum to the desired value. First, set each output to the maximum desired current limit the load can safely handle. Next, set the voltage of each output to sum to the desired voltage. For example, if you use two outputs, set each to one-half the desired voltage. If using three outputs, set each to one-third of the desired voltage. In addition, when you connect outputs in series for higher voltage, you should also take the following precautions:

- Avoid exceeding the floating voltage rating (output terminal isolation) of any of the outputs.

- Do not subject any power supply outputs to a reverse voltage.

- Only connect outputs that have identical voltage and current ratings in series.

If you use remote sensing, please wire the remote sensing terminals on each output in series and connect them to the load.

Keep the wiring from the power supplies to the load as short as possible. Twist or bundle the leads to reduce lead inductance and noise pickup. The goal is always to minimize the loop area or physical space between the + and - output leads from the power supply to the load.

You can connect power supplies in parallel to supply additional current to a device under test. Set the current limit of all outputs equally to the sum of the desired current limit value. The diagram below shows an illustration of two DC power supplies connected correctly in parallel:

It would be best if you also obeyed the following guidelines:

- One output must operate in constant voltage (CV) mode and the other(s) in constant current (CC) mode.

- The output load must draw enough current to keep the CC output(s) in CC mode.

- Only connect outputs that have identical voltage and current ratings in parallel.

- When you use remote sense in a parallel configuration, wire the remote sense terminals on each output in parallel and connect them to the load, as shown in the illustration above.

- Keep the wiring from the power supplies to the load as short as possible and twist or bundle the leads to reduce lead inductance and noise pickup. The goal is to minimize the loop area or physical space between the + and - output leads from the power supply to the load.

Set the voltage setting of the supply operating in CV mode slightly lower than the voltage setting of the supplies operating in CC mode. The supply set higher in voltage will push current into the load until it hits CC mode. After the supply reaches CC mode, its output voltage will reduce to the level of the other connected power supply’s voltage. Those supplies will then be regulated in CV mode and contribute to the remaining load current. The paralleled supplies must end up in different operating modes, such as CV or CC. Otherwise, they will fight with each other for control, and one will win, or they will oscillate the control back and forth, which is not desirable.

Want help or have questions?