Wafer-Level Component Measurements

Brochures

Wafer-Level Component Measurement

Keysight Technologies and Cascade Microtech

Guaranteed configuration, installation and support for accurate, repeatable waferlevel component measurements.

The specification of a test system to perform wafer-level measurements on components such as amplifiers, mixers and filters can be challenging, especially when a single wafer can include multiple component types. The tests required to validate these components are wide-ranging and complex, including S-parameters, DC-parameters, noise figure, gain compression and intermodulation distortion. Measurement and calibration accuracy is critical, especially when testing must be correlated between multiple locations.

To configure a system to meet these challenges you have to specify and source instrumentation, wafer probe stations, RF & DC probes and software from multiple suppliers, and then integrate and prove these on-site before your first device can be tested. It can take weeks or even months before you can execute your first measurements with the confidence that there is data correlation and measurement accuracy between different locations.

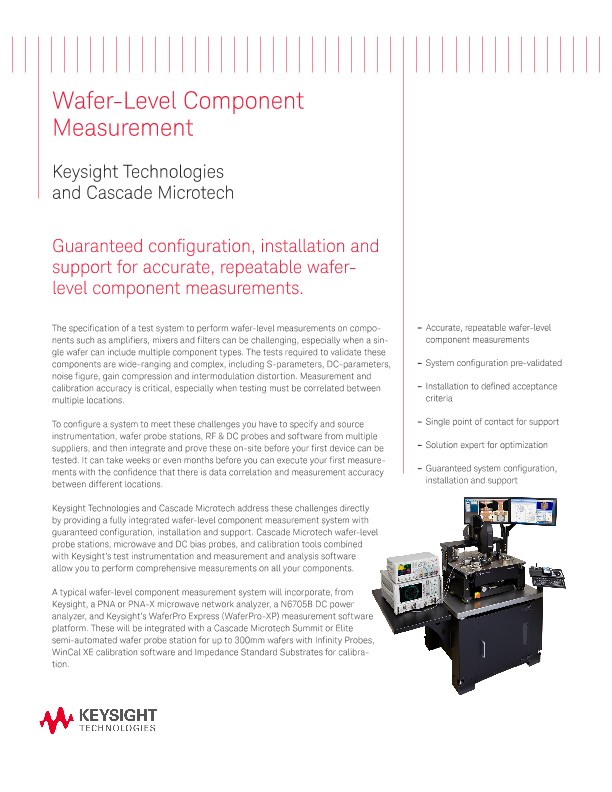

Keysight Technologies and Cascade Microtech address these challenges directly by providing a fully integrated wafer-level component measurement system with guaranteed configuration, installation and support. Cascade Microtech wafer-level probe stations, microwave and DC bias probes, and calibration tools combined with Keysight’s test instrumentation and measurement and analysis software allow you to perform comprehensive measurements on all your components.

A typical wafer-level component measurement system will incorporate, from Keysight, a PNA or PNA-X microwave network analyzer, a N6705B DC power analyzer, and Keysight’s WaferPro Express (WaferPro-XP) measurement software platform. These will be integrated with a Cascade Microtech Summit or Elite semi-automated wafer probe station for up to 300mm wafers with Infinity Probes, WinCal XE calibration software and Impedance Standard Substrates for calibration.

- Accurate, repeatable wafer-level component measurements

- System configuration pre-validated

- Installation to defined acceptance criteria

- Single point of contact for support

- Solution expert for optimization

- Guaranteed system configuration, installation and support

Wafer-Level Component Measurement

Measurement automation is critical to achieve the throughput and accuracy you need in your production and R&D environments. With WaferPro-XP you can setup and execute automated wafer-level measurements rapidly. WaferPro-XP’s interface and workflow are optimized for Cascade Microtech semi-automated probe stations.

To ensure all of these elements work together to meet your application needs, Cascade Microtech and Keysight will pre-validate the system configuration prior to delivery. Cascade Microtech solution experts will install, train and validate the system S-parameter and DC parametric performance and Keysight Technologies solution experts will verify optional application functionalities.

Installation is only judged complete when all agreed upon acceptance criteria are fully met. For ongoing support you will have a single point of contact at Cascade Microtech for quicker problem resolution. In addition, Cascade Microtech and Keysight have a team of wafer-level measurement solutions experts who will work with you to optimize the system to meet your continuing component measurement requirements.

With guaranteed configuration, guaranteed installation and guaranteed support, your wafer-level component measurement system from Cascade Microtech and Keysight gives you accurate and repeatable testing, minimizes the time to first measurement and ensures data correlation between multiple locations.

System Components