What are you looking for?

Fundamentals of EMC Pre-Compliance

Learn how pre-compliance testing ensures your devices pass final compliance testing and are ready to market on time.

Technology is rapidly evolving with many new electronic devices entering the marketplace. To ensure safe operation, and to guarantee quality and accuracy, compliance testing is necessary to sell your device. Pre-compliance testing allows you to cost-effectively reduce your time to market and certifies your product passing final compliance testing.

We will review the basics of pre-compliance tests, what you will need, and some of the measurements that you can perform to ensure your product passes.

Introduction – The Importance of Pre-Compliance Testing

With any product development, you first want to test the device to validate that it performs as expected. All electronic devices must pass electromagnetic interference (EMI) compliance tests at a certified in-house test facility. Passing the EMI tests demonstrates that your device's EMI emissions meet acceptable levels and conform to appropriate regulatory standards.

EMI falls under the umbrella term “EMC” which represents electromagnetic compatibility. When performing pre-compliance tests, you are concerned about testing for EMI, which is the actual electromagnetic phenomena — or emissions — coming from your device.

All products, from your laptop to your smartphone, have to pass compliance tests at a certified test-house. If your device does not pass the federally-mandated compliance tests, you cannot sell your product.

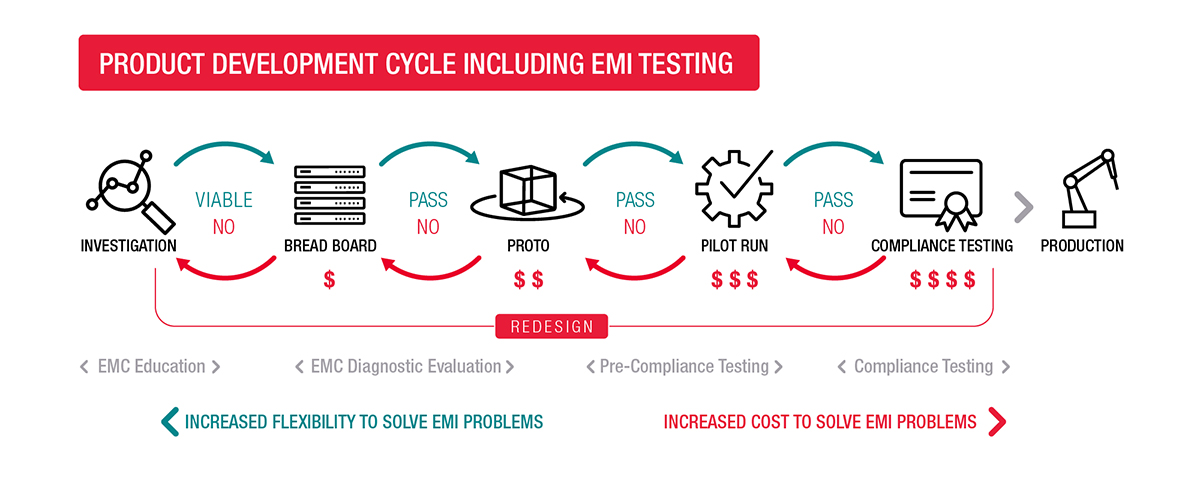

The final stage of compliance testing is usually expensive. If your product does not pass compliance testing, you not only have to rework your design but it will also impact your product development schedule. These delays affect your production cost and the product’s ability to enter the marketplace.

It is critical to perform EMC tests to ensure your device passes before the formal test-house certification.

The following information gives you a snapshot of everything you need to know about making EMC tests in your own environment; known as EMC pre-compliance testing. For a more detailed explanation, check out the material under the Suggested Reading section below.

Figure 1: The importance of pre-compliance testing in the product development cycle

Basics of EMC Pre-Compliance Testing

EMC is the interaction of electrical equipment with its electromagnetic environment and with other equipment. All electronic devices have the potential to emit electromagnetic fields, and compliance testing is the final stage of testing that ensures the electronic devices operate with safe EMI levels.

Certified test-houses perform various EMI tests to determine if your device has an appropriate level of emissions. These tests can be broken down into two categories – emissions testing and immunity testing. Within each of those categories, you have to perform both radiated and conducted tests.

- Radiated tests characterize unintentional electromagnetic energy released from an electronic device via a non-physical medium (cable testing).

- Conducted tests characterize unintentional electromagnetic energy released from an electronic device via a physical medium (cable testing).

Figure 2: Radiated and conducted emissions measurements characterize emissions to and from the DUT

EMC Pre-Compliance Terms You Need to Know

To understand EMI pre-compliance and how to perform the tests, it is helpful to know the key terms associated with it.

In this section, you will learn some of the relevant terminology applicable to EMI pre-compliance measurements.

Terminology

- EMC – Electromagnetic compatibility— the "umbrella term" for the unintentional generation, or propagation, of electromagnetic energy from a device.

- EMI – Electromagnetic interference

- Emission – the actual phenomena, or emissions tested during pre-compliance measurements. EMI can cause undesired interference with neighboring devices if not properly accounted for during design and test.

- Susceptibility- The characteristic of electronic equipment that permits undesirable responses when subjected to electromagnetic energy.

- Radiated Interference- Interference as a result from radio noise or unwanted signals over the air; not through a physical medium

- Conducted Interference- Interference resulting from conducted radio noise or unwanted signals entering a transducer (receiver) by direct coupling (via cables).

- CISPR- International Special Committee on Radio Interference which sets standards to supervise electromagnetic interference in electrical and electronic devices.

- LISN – Line Impedance Stabilization Networks — The LISN is important because it isolates power mains from the DUT, which needs to have as clean a signal as possible.

- Anechoic Chamber – A shielded room, designed to absorb sounds or electromagnetic waves and reduce reflections from all internal surfaces.

- Radiation- The emissions of energy in the form of electromagnetic waves.

- Immunity- The property of a receiver or any other equipment or system which enables it to reject a radio disturbance.

Pre-Compliance vs. Compliance Testing

Pre-compliance is a low-risk, cost-effective method to ensure your device under test (DUT) will pass final compliance testing. Waiting until the end of a product development cycle for compliance testing is risky due to its high cost. The cost of compliance testing includes reserving time in the compliance lab and redesigning your DUT if it does not pass compliance. Proper pre-compliance testing is crucial if you want to save money and avoid surprises during compliance testing.

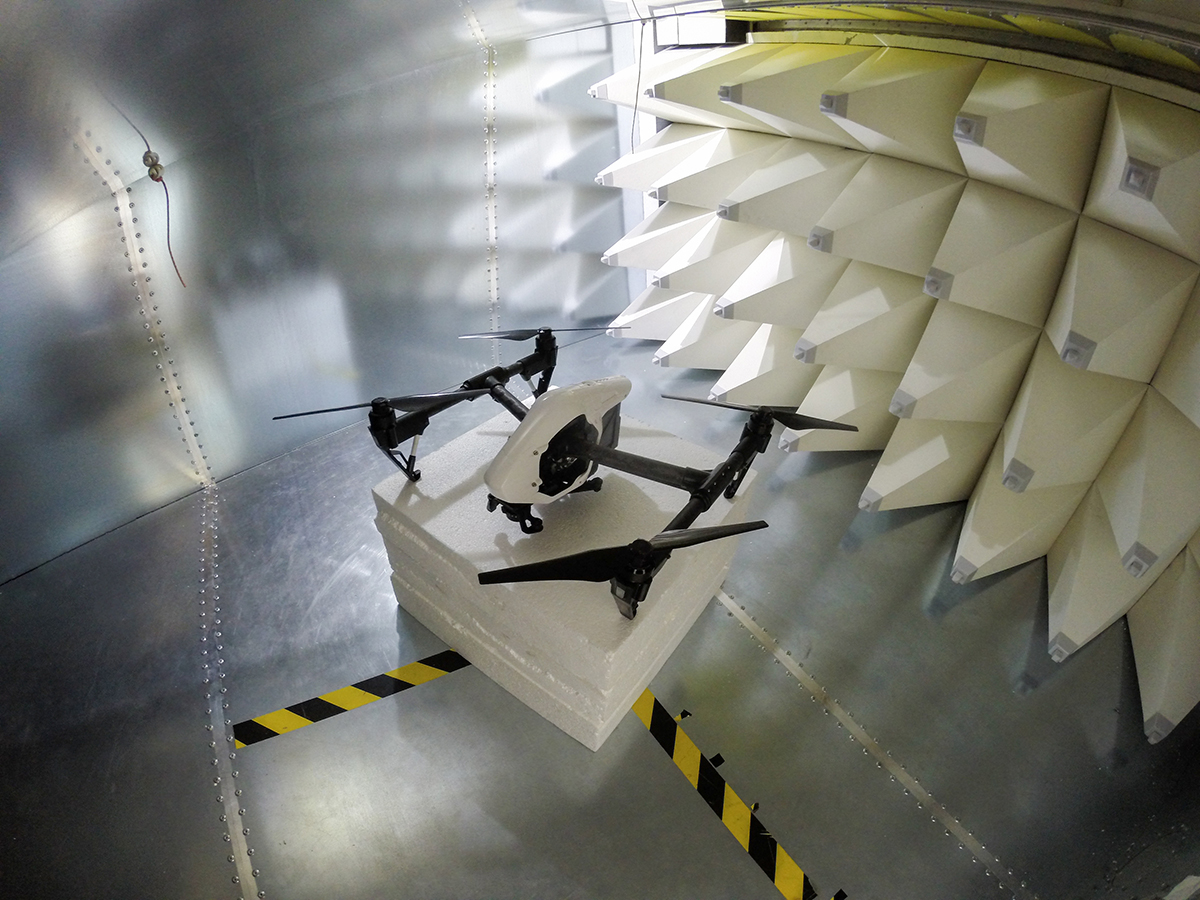

The key difference between pre-compliance and compliance testing is the formality and the usage of an anechoic chamber, as seen in the image below.

An anechoic chamber is a room designed to absorb reflection of electromagnetic waves — which is perfect for performing tests on an electronic device to ensure there is not any unexpected interference. In general, compliance testing is a formal process due to the anechoic chamber, as most electronic device manufacturers do not have an in-house chamber. These are often reserved ahead of time through a third-party group. These chambers are the key differentiator between pre-compliance and final compliance testing.

Figure 3: Using an anechoic chamber is the key difference between pre-compliance and final compliance testing.

Emissions Testing

Emissions testing measures the amount of electromagnetic energy emitted from your device. Emissions tests are important because you do not want your device to interfere accidentally with nearby devices.

Emissions testing includes two categories: radiated and conducted.

Radiated emissions tests quanitify the over-the-air electromagnetic energy strength of emissions from your device. They ensure these emissions from your device abide by the appropriate standard. Many devices fail this type of measurement, so invest some time in pre-compliance, radiated-emissions tesing.

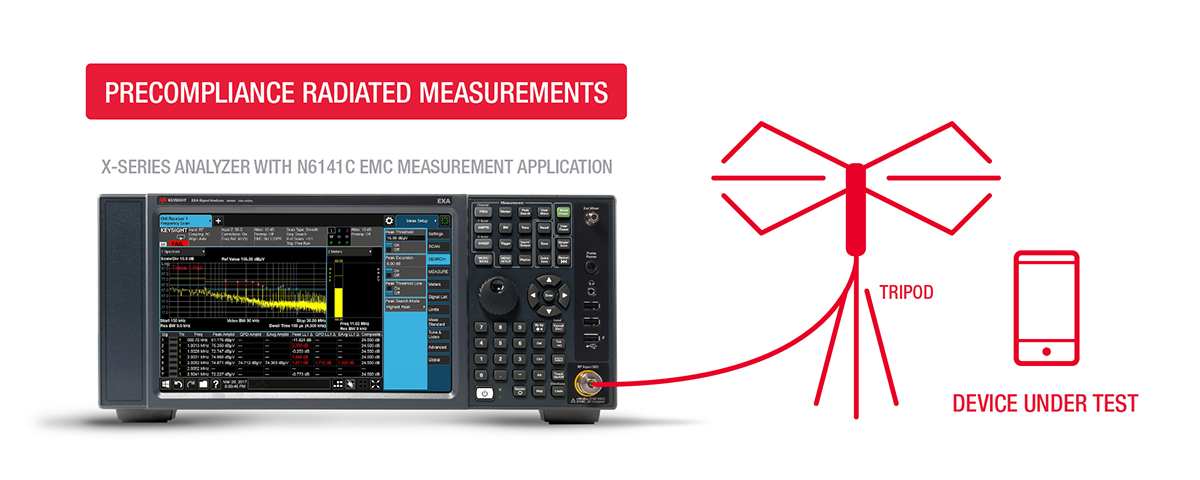

Figure 4: The equipment needed for a radiated emissions test includes a signal analyzer with pre-compliance software, antenna mounted on a tripod, and the DUT.

The required equipment for radiated emissions testing includes:

- Calibrated EMI antenna, mounted on a tripod, positioned 1 to 3 meters away from the DUT

- Spectrum analyzer equipped with EMC pre-compliance measurement software (Keysight N6141A EMI Measurement Application)

- Pre-amplifier

To avoid interference, you should perform radiated emissions tests far from other equipment. For example, you can use a large parking lot or an empty conference room. It is crucial that transmissions from broadcast radio, TV, or cell phones do not interact with your DUT or the antennas during the radiated emissions testing process.

Conducted RF emissions are electromagnetic disturbances created by electrical activity in the DUT that propagate out of the DUT along its interconnecting power, signal or data cables. Conducted disturbances travel along coupling paths from the DUT directly into other electronic devices. In addition, conducted disturbances can propagate within the device itself and negatively impact performance. Conducted emissions tests focus on these unwanted signals generated by the AC current of a DUT.

The required equipment for conducted RF emissions testing includes:

- Spectrum analyzer equipped with EMC pre-compliance measurement software (Keysight N6141A EMI Measurement Application)

- LISN (Line Impedance Stabilization Network)

- Limiter

Immunity Testing

Immunity testing determines how susceptible your device is to the electromagnetic energy emitted from other devices.

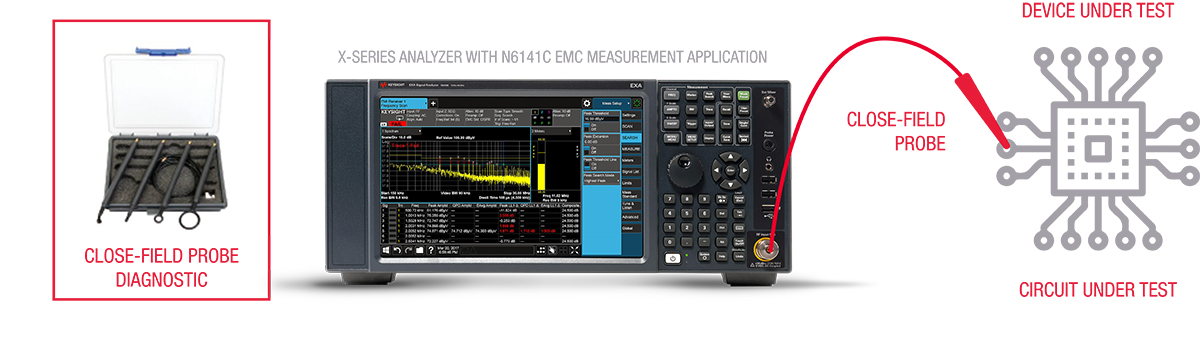

Radiated immunity tests entail testing the susceptibility of your device to over-the-air-emissions from other devices in the surrounding environment.

The required equipment for radiated immunity testing includes:

- Signal generator (Keysight MXG or EXG)

- Set of near-field probes

- Radio

Conducted immunity tests evaluate the susceptibility of your device and cables to EMI from other devices.

Immunity testing is important because you do not want your device influenced by the electromagnetic emissions from a neighboring device. Immunity testing is faster and easier than other pre-compliance test. CISPR standards do not require immunity tests, but we highly recommend them.

Figure 6: The equipment needed for a conducted immunity test includes a signal generator, signal analyzer, a set of near field probes, and the DUT.

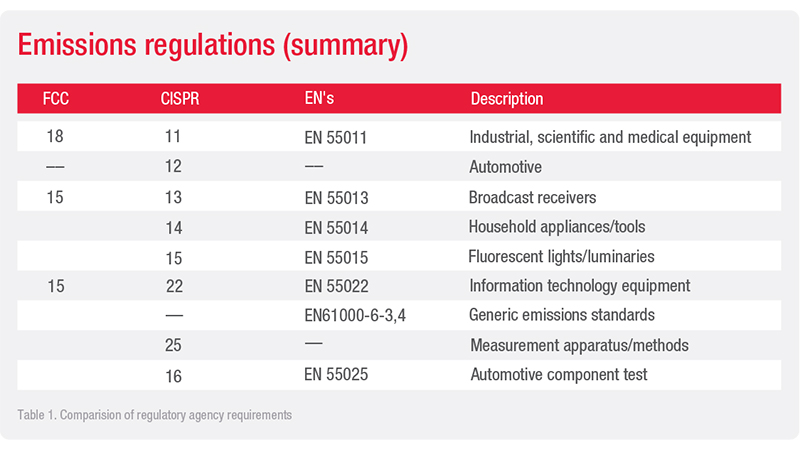

Understanding the EMC Compliance Process and the Regulatory Standards You Need to Meet

EMC tests ensure that your device performs to its design specifications without radiating emissions that threaten or degrade the performance of other equipment. EMC tests must meet strict emission standards, developed by EMC regulatory bodies, such as the Comité International Spécial des Perturbations Radioélectriques (CISPR). CISPR, the International Special Committee on Radio Interference determines the equipment and methods for measuring radiated EMI. Additionally, CISPR establishes the required levels of radiated emissions for electronic devices depending on the industry and the country that sells the product.

Before making measurements on your DUT, it is essential to ask yourself some preliminary questions:

- What countries will sell your product —Europe, United States, Asia Pacific, China?

- What is the classification of the product?

- Information technology equipment (ITE)

- Industrial, scientific, or medical equipment (ISM)

- Automotive

- Communication

- Generic/household items

- Where will the product be sold — home, commercial, industry

Your answers to these questions will help you determine the EMC standards for your products. Once you know the EMC standards for your product, you can plan for the necessary EMC test measurements.

The Benefits of Pre-Compliance Testing

EMC Pre-Compliance testing saves you time and costly rework. When you include EMC pre-compliance testing during the development process, you significantly improve the probability that your product will successfully pass full EMC compliance testing. Adding a pre-compliance test system is the optimum approach to achieving EMC compliance for your products, allowing you to cost-effectively reduce your time to market.

Figure 7: All electronics need to pass specific emissions regulations depending on what type of product it is and where it will be sold.

Product Information

Keysight Pre-Compliance Solutions

- Keysight X-Series analyzers help you design, test, and deliver with our most advanced signal analysis. Choose from a wide-open real-time analysis to low-cost essential measurements.

- The N6141A EMI measurement application is one in a standard library of more than 25 measurement applications in the Keysight X-Series. This application transforms the X-Series signal analyzers into a powerful EMI pre-compliance and diagnostic solution, providing easy-to-use data collection and analysis tools which facilitate rapid time-to-market for new designs.

Suggested Reading

The advantage of running an EMI pre-compliance test with a signal analyzer is that you can make a good estimation of the EMI performance of your new product and reduce the risk of failing EMI compliance at the end of a project.

For a better understanding of pre-compliance measurements, see the following Application Note, Making Radiated and Conducted Measurements for a better understanding of pre-compliance measurements.

Want help or have questions?