Introduction

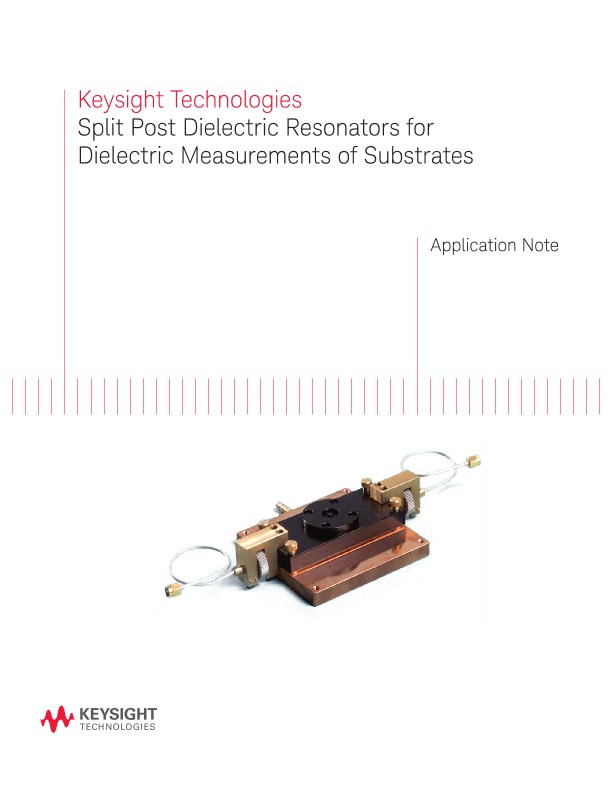

The Keysight Technologies, Inc. split post dielectric resonator (SPDR) provides an accurate technique for measuring the complex permittivity of dielectric and ferrite substrates and thin films at a single frequency point in the frequency range of 1 to 20 GHz. Besides the SPDR fixture, a vector network analyzer such as the PNA or PNA-L and software package 85071E option 300, are required for the measurement. The measurement is automatic and easy to perform.

Comparison With Other Methods

The microwave methods of measuring the dielectric properties can be divided into two main categories:

• transmission-reflection (e.g., measuring in coaxial line, waveguide, and free-space, or with open-ended coaxial line) and

• resonance methods

The SPDR measurement technique is one type of resonance method. The transmission-reflection methods offer swept measurement at “any” point in the frequency range over which they operate, while the resonance methods use a single frequency (or, at most, a few frequency points for different modes).

Resonators and cavities offer the highest available accuracy for measurements of real permittivity and allow for measurements of very low loss materials that cannot be measured with other techniques. A measurement at a discrete frequency point(s) should be adequate because lossless materials are nearly nondispersive. This means that their dielectric constant and loss tangent will stay constant over a range of frequencies.

The construction of the SPDR uses new, low-loss dielectric materials which make it possible to build resonators having higher Q-factors and better thermal stability than traditional all-metal cavities 2,3. The main advantages of the SPDR are:

• superior accuracy compared to transmission-reflection methods

• ability to measure low loss materials (lower loss materials that cannot be measured with the transmission-reflection technique)

• convenient, fast, and nondestructive measurement of substrates, printed circuit boards, and even thin films

Sample Geometry

This method is nondestructive, if the substrate can fit in the SPDR, because no special sample preparation is needed. The electric field in the resonator is parallel to the surface of the sample as shown in Figure 1. The main sample requirements are: two strictly parallel faces, the thickness of the sample h in Figure 1, must be less than the fixture air gap hG (see Figure 4), and the sample must have enough area to cover the inside of the fixture. The air gap between the sample and the dielectric resonator (see Figure 4) does not affect the accuracy of the measurement. The sample may have a rectangular or round shape as shown in Figure 1. For easy handling of the sample, it is recommended that the sample area dimension L be bigger than the dimension of the minimum measurable area l (or active area of the fixture).

The required thickness of the sample also depends on the dielectric constant e‘r of the material. Materials with high dielectric constants must have less thickness. Figure 2 shows the typical resonant frequency f versus permittivity e‘r in the case of a 10 GHz SPDR. For this fixture, if the permittivity of the sample e‘r is less than 10, the maximum sample thickness must be smaller than the fixture gap thickness hG. At the same time, the sample must also be thick enough to create enough frequency shift to be easily measured. If the sample permittivity e‘r is greater than 10, the sample thickness may have to be reduced to keep the frequency shift within the recommended range. The thickness should be chosen from Figure 2, knowing that the frequency should not be much smaller than 8.5 GHz.

The fixture air gap hG and the active area dimension l of the fixture depend on the operating frequency f of the resonator. Table 1 shows approximate values of these dimensions for resonators operating at different frequencies. The sample dimension L should be less than Lf , which is the maximal dimension that the fixture can accommodate.

The SPDR technique can also be used for measuring thin films. Figure 3 shows the typical resonance frequencies f versus the permittivity for a 10 GHz resonator. If the film is deposited on a substrate, the resonant frequency shift due to the presence of the thin film is very similar to Figure 3 (differences are about 1 to 2 percent). To separate the frequency shift of the film from the overall frequency shift of the substrate and the film, the substrate alone should be measured initially (without film).

Permittivity and loss tangent of thin films deposited on substrates having a diameter > 20 mm can be evaluated directly with systematic 1 to 2 percent error using the same program as for uniform dielectrics. In this case one has to measure the empty resonator (f01,Q01), empty resonator with a substrate only (fs,Qs), and, after film deposition, repeat the measurement of the empty resonator (f02, Q02) and resonator with film and substrate (f2,Q2). The film should face down during this measurement.

Oscilloscopes

Analyzers

Meters

Generators, Sources, and Power Supplies

Software

Wireless

Modular Instruments

Network Test and Security

Network Visibility

Services

Additional Products