Accuracy and peak performance are keys to competitive success in today’s lean factory environment. Your customers are asking for tighter tolerances and reduced costs. You want to control shop operations, reduce scrap, re-work, and improve productivity. Meeting these challenges means that you need to maximize the performance of your machine tools and, as a result, machine tool calibration has never been more important.

For more than four decades, Keysight technologies, Inc. Laser Calibration System have set the standard for laser-based metrology systems used to calibrate and verify machine tool and CMM accuracy. We introduced the first laser calibration system and continue to offer industry leading performance.

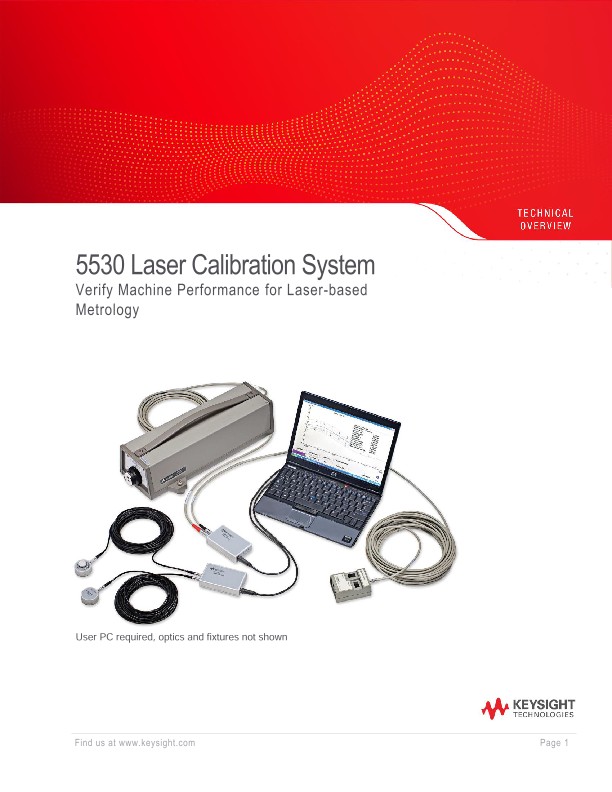

Users benefit from improved process control and efficiency that help to optimize shop operations and reduce overall production cost. And, the powerful measurement capability of Keysight’s NIST traceable Laser Calibration System enables manufacturers to conform to key international standards. The Keysight 5530 Laser Calibration System is the ideal measurement tool to help manufacturers improve process control and efficiency for CMM and machine tool operations.

A powerful system that...

- Measures machine tool positioning accuracy

- Provides compensation data used to correct machine positioning error

- Aids in diagnosing geometry problems

- Documents machine performance in international standards

- Provides production managers with known performance for each machine.

International standards

- ANSI B5.54 / B5.57

- BSI 3800

- GB 10931

- GB/T

- ISO 230-2

- JIS B6330

- NMTBA

- VDI 3441 / 2617

Verify Machine Performance and Improve Process Control

Customers continue to make demands on machine shops for more precise parts, manufactured to tighter specs. In order to maintain low inventories and trim cash flow, manufacturers want quick turnaround on parts. Short part runs, often using expensive materials, have become more common.

To help machine shops succeed in this increasingly competitive environment, Keysight designs and manufactures the 5530 Laser Calibration System with unmatched repeatability and reliability, making it the most cost-effective laser calibration system availabl

Machine tool manufacturers use the 5530 Laser Calibration System to:

- Respond to customer requests for acceptance testing at installation.

- Avoid expensive troubleshooting at the customer site by ensuring all machines meet specifications before they leave the factory.

- Give customers documented performance of their equipment as it leaves the factory by merely hitting a button on the screen. In any of eight languages. To key international standards and NIST traceable.

- Monitor and control the building process by recording the capability of every machine produced.

- Identify performance errors and make improvements in machine tool design.

- Reassure customers that their machine has passed the test of the toughest laser calibration system – the 5530 heterodyne laser interferometer that is the most rugged and accurate calibration method available.

- For machine tool manufacturers who provide their customers with regular calibration service, the 5530 fits into a single transit case. When needed the tripod comes in its own wheeled transit case that can piggyback on the system case.

The building blocks you need to improve process control and reduce costs allow you to:

- Improve machine performance

- Meet the most demanding design and tolerance specifications

- Reduce scrap and re-work

- Decrease trim waste

- Lower overall cost of shop operations

When Should You Calibrate?

The 5530 Laser Calibration System helps you control quality and maximize productivity from the day your machine tool is delivered:

Acceptance testing

Machine tool manufacturers carefully test your equipment for accuracy before it leaves the factory, however equipment

often loses accuracy during shipment and installation. By calibrating with the 5530 Laser Calibration System, you prevent costly performance problems and ensure that your new investment begins paying its way immediately.

Scheduled calibration

Just as regular maintenance increases the life of your automobile, periodic calibration increases the life of your machine tool.

Keysight Technologies recommends that new machine tools be calibrated every six months during the first year-and-a-half of operation and then annually, unless calibration results warrant more frequent calibration. If environmental factors are extreme or if the machine tool is subjected to high stress or a crash, users should calibrate at shorter intervals.

Scheduled calibration with the 5530 provides a complete picture of your machine tool performance so that you can efficiently schedule workflow. You can schedule the most demanding work on the most accurate machines. And by identifying machines that cannot meet the accuracy requirements for a given job, the 5530 helps you control your processes, so you avoid costly scrap and schedule slips

Oscilloscopes

Analyzers

Meters

Generators, Sources, and Power Supplies

Software

Wireless

Modular Instruments

Network Test and Security

Network Visibility

Services

Additional Products